Ama-brass amaningiziyisixazululo esisebenza kahle kakhulu sohlu lwezinhlelo zokusebenza zokulawula uketshezi, kusukela kumasistimu okushisa nawokupholisa kuya ekulawuleni inqubo yezimboni. Izakhiwo eziyingqayizivele zethusi ziyenza ibe yinto efanelekile kakhulu yokukhiqiza okuhlukahlukene, ukuyibeka ngaphandle kwezinye izinto ezisetshenziswa kulo mongo. Kulesi sihloko, sizohlola ukuthi yini eyenza ama-nifolds ethusi ahluke kulezo ezenziwe kwezinye izinto.

Ukuqina Okuphakeme Nokuqina

Ithusi liyinto ehlala isikhathi eside futhi eqinile, ekwazi ukumelana nokuguga okuhlobene nokusetshenziswa okuqhubekayo ngaphansi kwezimo ezinzima. Ngakho-ke ama-nifold ethusi ayakwazi ukugcina ubuqotho nokusebenza kwawo isikhathi eside, ngisho nasezindaweni ezinomfutho ophezulu kanye nezimoshekayo. Lokhu kwenza ukuphindaphindeka kwethusi kube ukukhetha okuhle kakhulu kwezinhlelo zokusebenza lapho ukwethembeka nokuphila isikhathi eside kubalulekile.

I-Thermal Conductivity enhle

I-Brass ine-conductivity enhle kakhulu ye-thermal, iyenza ifanelekele ukusetshenziswa ezinhlelweni zokufudumeza nokupholisa. Ama-manifold ethusi ayakwazi ukusabalalisa ukushisa noma ukupholisa kahle ezindaweni ezihlukahlukene ohlelweni, okuqinisekisa ukulawulwa kwezinga lokushisa okufanayo kanye nokusebenza kahle kwesistimu. Lesi sici sethusi siphinde sikhuthaze ukuqalisa kwesistimu okusheshayo nokuvala shaqa, kanye nokulawulwa okunembile kwezinga lokushisa.

Kulula ukufaka nokugcina

Ama-nifold ethusi kulula ukuwafaka nokuyinakekela uma kuqhathaniswa nama-multifolds enziwe ngezinye izinto. I-Brass iyimpahla ethambile, eyenza kube lula ukuyifaka nokwakheka ngesikhathi sokukhiqiza. Lokhu kusho ukuthi ukuphindaphindeka kwethusi kungenziwa ngendlela oyifisayo kalula ukuze kulingane izinhlelo zokusebenza ezithile, kuncishiswe isidingo sokulungiswa okwengeziwe noma okokufakwayo ngesikhathi sokufakwa. Ukwengeza, ama-multifolds ethusi kulula ukuwahlakaza nokuhlanza ngesikhathi sokulungiswa, okwenza kube lula inqubo yokuhlola nokulungisa noma yiziphi izinkinga ezingase ziphakame.

Ukumelana Nokugqwala

I-Brass imelana kakhulu nokugqwala, ngenxa yokuhlanganiswa kwayo kwe-alloys yethusi ne-zinc. Lokhu kusho ukuthi ama-nifold ethusi ayakwazi ukumelana nohlu lwama-asidi, ama-alkali, nezinye izinto ezigqwalile ezivame ukutholakala ezinqubweni zezimboni. Ahlala esebenza kulezi zindawo, ngaphandle kokuguga noma ukulimala. Lokhu kwandisa isikhathi sabo sokuphila futhi kuqinisekisa ukusebenza kahle kwazo kwesikhathi eside, ngisho nasezimeni eziyinselele.

Iyakhanga futhi Ibiza izindleko

Ama-manifold ethusi aphinde anikeze ukubukeka okukhangayo, okunethoni efudumele ehlukile ehlangana kahle nezilungiselelo eziningi zezimboni. Lesi sikhalazo sobuhle singasiza ukuthuthukisa ukubukeka kwayo yonke indawo, kuyilapho kwengeza inani kumklamo wonkana. Ukwengeza, ithusi libiza kakhulu uma liqhathaniswa nezinye izinto zokwakha, njengensimbi engagqwali noma i-titanium. Lokhu kwenza ukuphindaphindeka kwethusi kube ukukhetha ukonga kwezinhlelo zokusebenza eziningi, ngaphandle kokudela ukusebenza noma ukuqina.

Ukuvumelana nezimo kusayizi nokucushwa

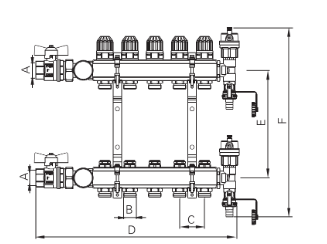

Ama-nifold ethusi atholakala ngebanga losayizi nokucushwa, okwenza kube lula ukuzijwayeza kumasistimu okulawula uketshezi oluhlukene. Noma ngabe udinga i-manifold encane yesistimu yokushisisa yasekhaya noma enkulu yenqubo yemboni, ama-brass manifold ngokuvamile angenziwa ngendlela efanele ukuze ahlangabezane nezidingo zakho ezithile. Lokhu kuvumelana nezimo ekwakhiweni kusho ukuthi ukuphindaphindeka kwethusi kungasetshenziswa ezinhlotsheni ezihlukene zezinhlelo zokusebenza, kusukela kwezindawo zokuhlala kuye kwezokuhwebelana nezimboni.

Sengiphetha, ama-manifold ethusi ahlukile ngenxa yokuqina kwawo okuphezulu nokuqina, ukuguquguquka okuhle kwe-thermal, ukufakwa kalula nokulungiswa, ukumelana nokugqwala, ukubukeka okukhangayo, ukuphumelela kwezindleko, kanye nokuguquguquka kosayizi nokucushwa. Inhlanganisela yalezi zici yenza ithusi libe into efanelekile kakhulu yokukhiqiza okuhlukahlukene, okuqinisekisa ukuphila isikhathi eside nokusebenza kahle ezinhlobonhlobo zezinhlelo zokusebenza zokulawula uketshezi.

Isikhathi sokuthumela: Sep-29-2023