Ukuxuba uhlelo lwamanzi /Isikhungo sokuxuba amanzi

| Isiqinisekiso: | iminyaka engu-2 | Isevisi yangemuva kokuthengisa: | Ukusekelwa kwezobuchwepheshe ku-inthanethi |

| Isicelo: | Ifulethi | Isitayela Sokuklama: | Okwesimanje |

| Indawo Yomsuka: | I-Zhejiang, China | I gama le-brand: | ILANGA |

| Uhlobo: | Amasistimu okushisa aphansi | Amagama angukhiye: | Uhlelo Lokuxuba Amanzi Ethusi |

| Umbala: | I-Nickel plated | Usayizi: | 1" |

| I-MOQ: | 5 amasethi | Igama: | Uhlelo lokuhlanganisa amanzi |

| Inombolo Yemodeli | XF15231 | ||

| I-Brass Project Solution Amandla | idizayini yezithombe, idizayini yemodeli ye-3D, isixazululo esiphelele seProjekthi, Ukuhlanganisa Izigaba Zesiphambano | ||

Izinto zomkhiqizo

I-Brass Hpb57-3 (Ukwamukela ezinye izinto zethusi ezicaciswe yikhasimende, njenge-Hpb58-2, Hpb59-1, CW617N, CW603N njalonjalo)

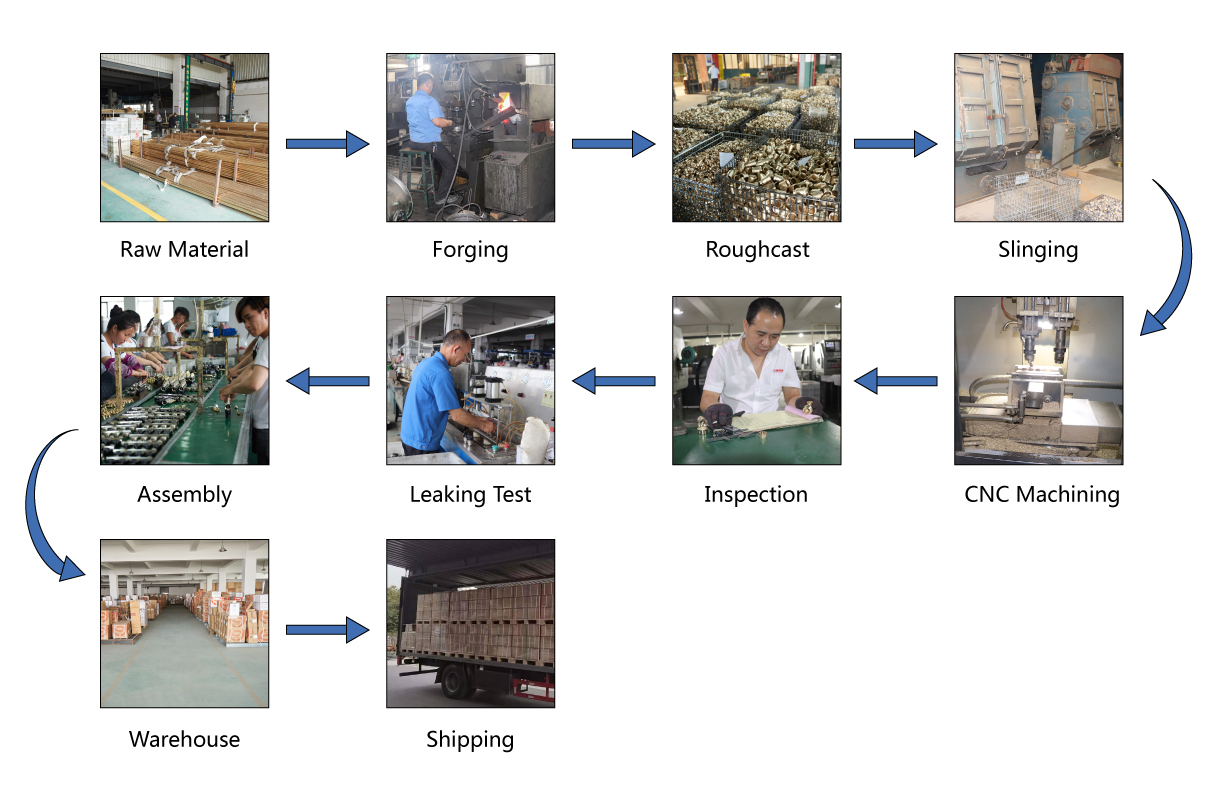

Ukucubungula Izinyathelo

Ukusuka kokusetshenziswa okuluhlaza kuye kumkhiqizo oqediwe, inqubo nge-Raw material, i-forging, roughcast, slingling, CNC machining, ukuhlola, ukuhlolwa okuvuzayo, umhlangano, ekugcineni ukupakisha kanye ne-warehouse, ukuthunyelwa.

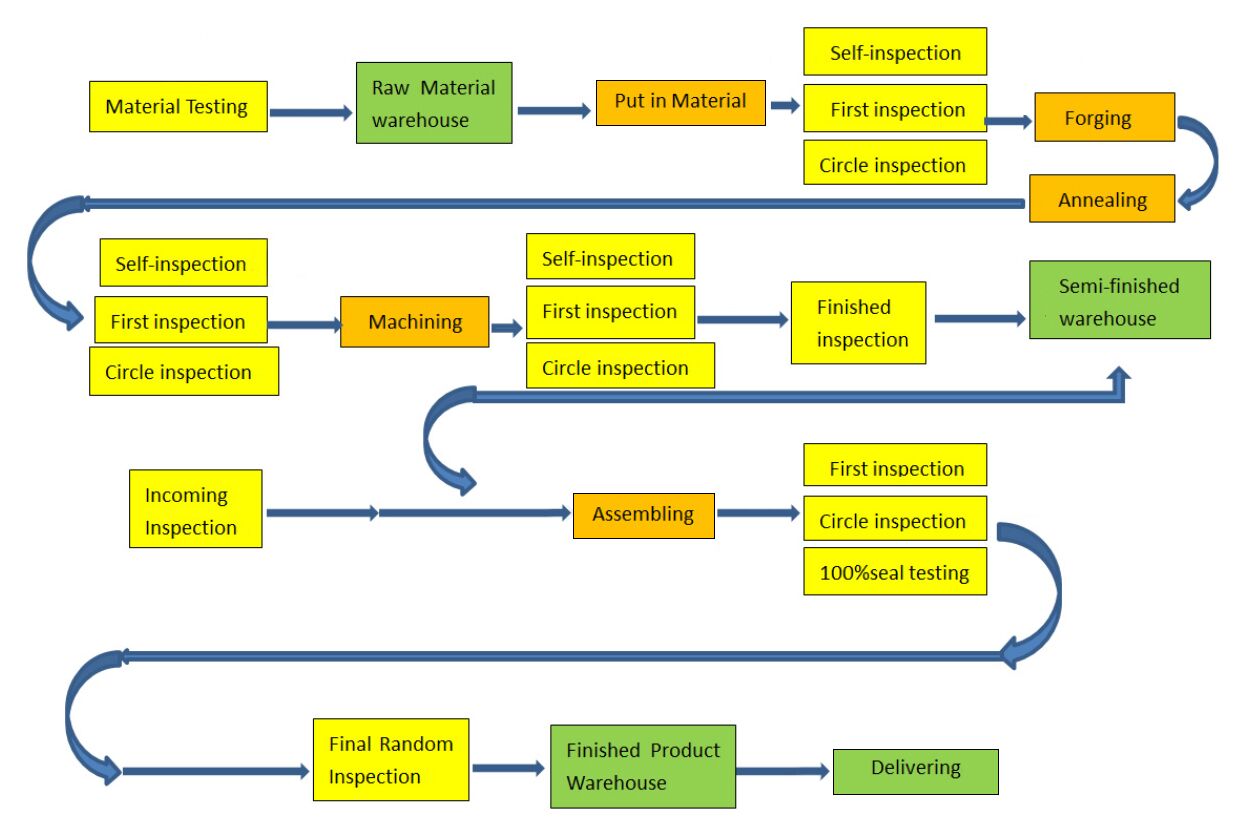

Ukuhlola Material, I-Raw Material Warehouse, Faka impahla, Ukuzihlola, Ukuhlola Kokuqala, Ukuhlola Umbuthano, Ukufoja, Ukunezela, Ukuzihlola, Ukuhlola Okokuqala, Ukuhlola Umbuthano, Umshini, Ukuzihlola, Ukuhlola Kokuqala, Ukuhlola Umbuthano, Ukuhlola Okuqediwe, Ukuhlolwa Kwendlu Encane, Ukuhlolwa Kokuqala, Ukuhlolwa Kwendlu Encane Ukuhlolwa, Ukuhlolwa Kwezimpawu Ezingu-100%, Ukuhlolwa Kokugcina Okungahleliwe, Indawo Yokugcina Yomkhiqizo Eqediwe, Ukudiliva

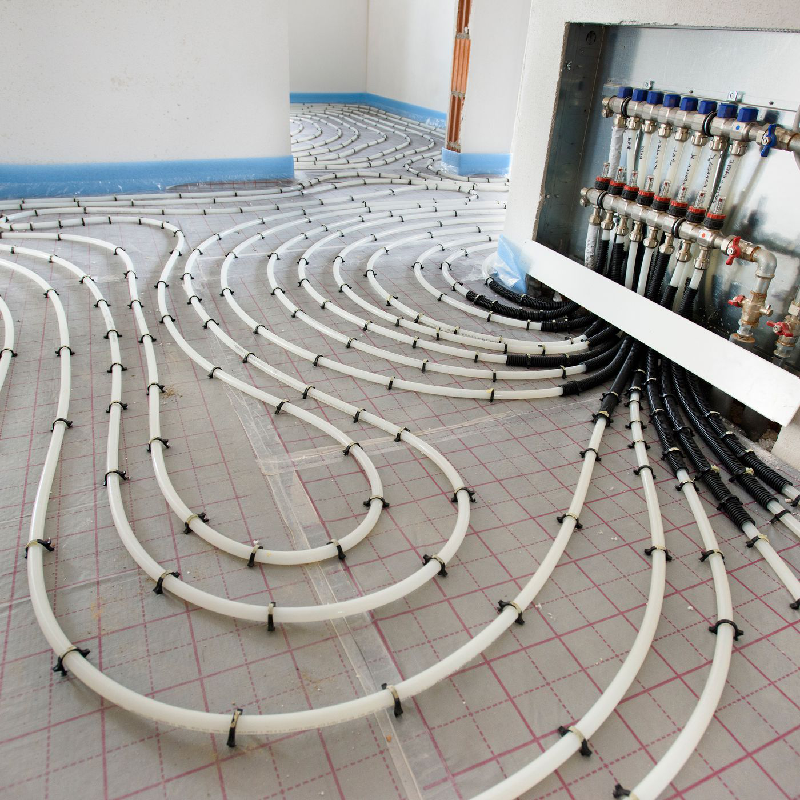

Izinhlelo zokusebenza

Amanzi ashisayo noma abandayo, ahlukahlukene okushisa phansi, isistimu yokufudumeza, uhlelo lokuxutshwa kwamanzi, izinto zokwakha njll.

Izimakethe Eziyinhloko Zokuthekelisa

Europe, East-Europe, Russia, Middle-Asia, North America, South America njalonjalo.

Incazelo Yomkhiqizo

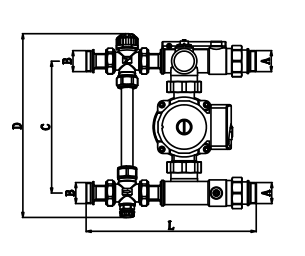

Isikhungo sokuxuba amanzi siwukushisa kwamanzi kanye nesistimu yokulawula ukugeleza okuhlanganisa ipompo yamanzi ejikelezayo, i-valve yokulawula kagesi, i-valve yebhola ene-thermometer, isilawuli, inzwa yokushisa, i-valve yokuhlunga, kanye nedivayisi encane yokubamba.

Indima yesikhungo sokuxuba

Isikhungo sokuxuba amanzi silungisa izinga lokushisa lamanzi okushisa aphezulu anikezwa i-boiler elenga odongeni nge-thermostat ne-valve yokulawula, futhi iwaguqule ibe amanzi aphansi okushisa adingekayo ekushiseni kwaphansi.

Ngenkathi ulungisa izinga lokushisa lamanzi, iphampu yokujikeleza ingasetshenziswa futhi ukulungisa izinga lokugeleza ukuze kuthuthukiswe ukunethezeka okuphelele kokushisa phansi.

Ngaphezu kwale misebenzi emibili eyinhloko, isikhungo sokuxuba amanzi siphinde sibe nemisebenzi efana nokunciphisa ukuguquguquka kwezinga lokushisa lokuphuma kwamanzi kubhayela olenga odongeni.

Uma kucatshangelwa ukuphepha nokunethezeka kokushisa kwaphansi, izinga lokushisa lamanzi okushisa phansi elidingwa yizinga likazwelonke alikho ngaphezu kuka-60 ℃, futhi izinga lokushisa elifanele lingu-35 ℃ ~ 45 ℃.

Uma izinga lokushisa lokukhipha amanzi le-boiler elenga odongeni libekwe ku-45 ° C, lizoba sesimweni sokusebenza komthwalo ophansi, futhi ukusebenza kahle kokushisa kuzovame ukuba ngaphansi kwenani elifanele, elibuye lilethe izinkinga ezimbili:

1. Ukusebenza okuphansi kwezinga lokushisa kwe-boiler elenga odongeni kungenzeka kubangele ukuqala nokumiswa njalo kwemishini, okuzokwandisa ukusetshenziswa kwamandla futhi kuthinte impilo yesevisi ye-boiler elenga odongeni.

2. Ukushiswa okunganele kwegesi kukhulisa idiphozithi ye-carbon yama-boilers alenga odongeni, okuthinta ukusetshenziswa okuvamile kwama-boilers alenga odongeni isikhathi eside.

I-PS: Uma kuyisithando somlilo esijiyayo esifanele ukusebenza kwezinga lokushisa eliphansi, izinkinga ezingenhla ngeke zenzeke.

Ukufakwa kwesikhungo sokuxuba amanzi kuvumela umthombo wokushisa we-boiler olenga odongeni kanye netheminali yokushisisa phansi ukuthi isebenze ezimeni ezifanele zokusebenza ngasikhathi sinye, okuthuthukisa ukusebenza kahle kwesistimu futhi kunciphise ukuqala nokumiswa njalo kwe-boiler elenga odongeni ngokwezinga elithile.

Okwesibili, isikhungo sokuxuba amanzi sizohlinzeka ngokushisa kwamanzi okunembile nokugeleza ngokuvumelana nezidingo zekamelo. Nakuba kuthuthukisa ukunethezeka, futhi kunciphisa ukusetshenziswa kwamandla ngezinga elithile.